I. Overview

During long-term operation, the high-temperature and high-pressure pipelines on the heating surfaces of coal-fired boilers are prone to developing defects such as localized pipe wall thinning, wear, erosion, and corrosion. These issues arise due to exposure to flue gas, fly ash, steam-water scouring, and high-temperature chemical reactions. Ultimately, these defects may lead to tube bursts, resulting in significant economic losses.

Traditional inspection methods involve setting up scaffolding or large lifting platforms to conduct anti-wear and explosion-proof inspections on elevated wall surfaces such as water-cooled walls, high-temperature superheaters (high-over), and high-temperature reheaters (high-reheat). Inspectors are required to wear safety harnesses, carry equipment, and work at heights of dozens of meters, posing potential safety hazards. This approach takes substantial working hours,resources, and high cost, while also carrying a high risk of accidents. Power plants urgently need a new inspection method during short-term boiler shutdowns with intelligent detection devices to perform early preventive inspections on the internal tube panels.

II. Flexible Guide Rail Robot

The flexible anchor line robot primarily composed of a flexible anchor line traveling mechanism, rigid rails, detection modules, terminal control modules, and positioning modules.

1.Flexible Anchor Line Traveling Mechanism

The flexible anchor line module includes horizontal anchor line, vertical anchor line, and two traveling mechanisms. The traveling mechanisms are driven by friction between guide wheels and the flexible anchor lines, enabling stable vertical or horizontal movement. They can achieve a travel speed of up to 8m/min and a maximum load capacity of 180kg. These mechanisms can safely carry various inspection instruments such as thickness gauges, oxide scale detectors, and digital radiography imaging equipment, eliminating the risk of dropping.

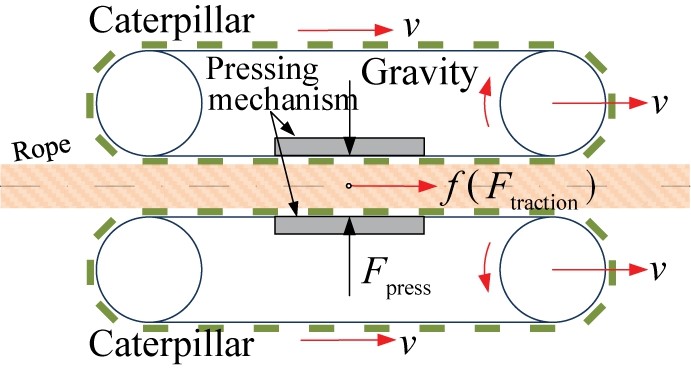

The basic working Principle of travling mechanism

The horizontal anchor line is anchored at both ends to the boiler’s roof or viewing ports on the water-cooled walls, with wire tensioners installed to ensure stable operation of the traveling mechanism. The upper end of the vertical anchor line is fixed to the base of the traveling mechanism, allowing it to move reciprocally. By combining horizontal and vertical anchor line, a coordinate system covering the entire water-cooled wall tube panel can be established. This enables the inspection probe to reach any position and achieve full-coverage detection without blind spots.

water-cooled magnetic guide rail and thickness measurement probe

The rigid guide rails are suspended from the vertical traveling mechanism and move vertically with it. Upon reaching the inspection position, electromagnets at both ends of the guide rails are energized and magnetized to adhere to the target tube panel. This ensures stable lateral movement of the thickness measurement probe along the guide rails. After thickness measurement is completed, the electromagnets are de-energized and demagnetized, allowing the entire system to move to the next inspection point.

The electromagnetic ultrasonic thickness measurement requires no couplant and tolerates surface deposits such as slagging (<2 mm), loose rust, or unevenness on the workpiece. It enables rapid and continuous wall thickness measurements, with stable data transmission to the controller. During inspection, the thickness sensor automatically adapts to tube arrays of varying specifications, achieving continuous thickness measurements for water-cooled wall tubes of different diameters. The measurement accuracy is ±0.1 mm, and inspection reports can be generated with a single click.

The robot can also be equipped with a high-definition camera for integrated visual inspection. The camera offers a maximum resolution and frame rate of 1920×1080@30 fps. While assisting mechanical clamps in securing positioning, it enables real-time monitoring of defects on the tube panel surface, including cracks, impact damage, deformations, wear, bulges, and corrosion.

2.2 high-temperature superheaters (high-over), and high-temperature reheaters (high-reheat) inspection

oxide

coating detection probe and mechanical Clamps

During X-ray inspection, two sets of flexible anchor lines are installed on both sides of the tube panel. The robot can move to any point and secure itself via mechanical clamps. Cold cathode X-ray machines and imaging plates are installed on both sides, enabling synchronized movement and real-time imaging. When detecting oxide scale accumulation in austenitic elbows, a robotic arm equipped with an oxide scale detector probe is installed on the flexible guide rails to perform quantitative measurements of oxide buildup in the elbows. A thickness gauge can also be integrated onto the robotic arm to measure tube wall thickness in real time during the inspection.

1.Control Module

The

control box manages the robot’s movement, inspection, and communication through

a human-machine interface (HMI).

The robot management system software, integrated into the terminal control

system, enables functionalities such as real-time imaging and inspection data

monitoring, robot control, path planning, as well as data storage, display, and

export.

2.Positioning Module

The robot employs laser ranging and vision-assisted positioning to ensure high control accuracy, while an encoder automatically records the identification numbers of inspected tubes. Additionally, spray-marking at defect locations facilitates post-inspection review and defect removal process.

III. Advantages Analysis

1.Safety

The application of the flexible guide rail robot significantly reduces the need for personnel to directly enter hazardous environments within the furnace. The robot is operated via remote control, allowing workers to monitor the inspection process from a safe location.

Furthermore, the design of the flexible guide rail minimizes the risk of falls from heights, eliminating the need for fall arresters, concerns about the robot’s adhesion force on walls, or obstacle-crossing challenges. With a load capacity that accommodates various commonly used inspection equipment, the system ensures comprehensive safety throughout the entire process.

2.Comprehensiveness

The dual flexible guide rail design enables 360° blind-spot-free coverage of the inspected tube panel. The robot can simultaneously carry multiple inspection probes (e.g., thickness gauges, radiography imaging devices, oxide scale detectors) to perform tasks such as wall thickness measurement, crack detection, oxide scale assessment, wear evaluation, and corrosion inspection. The integration of multiple inspection results allows for highly efficient and holistic evaluations.

3.Flexibility

The flexible guide rail robot is designed for rapid deployment and ease of operation. Its horizontal and vertical mobility ensures quick access to inspection points. Equipped with robotic arms or mechanical clamps, it adapts to various tube panel configurations. The modular system design allows customization based on the specific needs of power plants. The automated inspection process is fast and precise, drastically reducing inspection downtime and maintenance periods, thereby enhancing operational efficiency.

4.Traceability

The robot system incorporates built-in data processing and storage capabilities, enabling real-time collection and analysis of inspection data to generate detailed reports. This data can be used for trend analysis, predicting potential failures, and assessing equipment lifespan, aiding in the development of more effective maintenance strategies. Additionally, the precise recording of data facilitates historical traceability and accountability tracking.

IV. Summary

Short-term unit shutdowns represent a pain point and a critical gap in meeting the requirement of "mandatory inspections during every boiler shutdown." By deploying the flexible guide rail robot system, automated collection of operational status data for power plant boiler tube panels can be achieved. This replaces manual inspections in hazardous environments, enhances the efficiency of anti-wear and explosion-proof checks, and enables full-coverage, blind-spot-free inspections that were previously unattainable. Additionally, it ensures safety assurance at a lower cost.